Product Details

Product Introduction

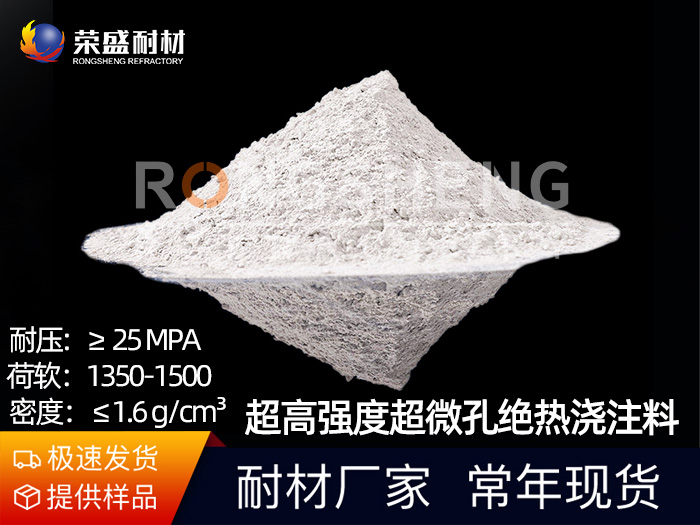

The ultra-high strength ultra-microporous thermal insulation castable developed meticulously by Rongsheng Kiln Refractory Co., Ltd. stands as a premier energy-efficient and eco-friendly refractory solution. This product is crafted from a scientifically balanced mixture of lightweight ultra-microporous aggregate, high-temperature aluminate cement, alumina powder, and specially chosen additives, showcasing remarkable attributes. It features exceptional compressive strength while maintaining low thermal conductivity. Its superior thermal insulation capabilities significantly lower energy consumption in industrial kilns, driving energy savings and minimizing waste. Furthermore, the product is straightforward to install, making it suitable for a variety of high-temperature applications in sectors such as power generation, metallurgy, and petrochemical industries. Rongsheng Company employs a rigorous quality assurance system to guarantee that every batch adheres to meticulous standards, ensuring safe and efficient operation for numerous kiln projects.

Advantages and features

1. Exceptional strength and efficiency: Our product is engineered to possess ultra-high compressive strength, guaranteeing its long-term durability and stability; 2. Advanced ultra-microporous technology: This innovative technology significantly minimizes thermal conductivity, enhancing overall thermal insulation performance; 3. Energy efficiency and cost reduction: Outstanding thermal insulation capabilities greatly diminish kiln heat loss, facilitating optimal energy usage and financial savings; 4. Easy installation: The product is designed for straightforward application, allowing quick adaptation to the construction needs of various industrial high-temperature systems; 5. Consistent quality: A rigorous quality control process ensures that each batch of products maintains reliability and uniformity; 6. Eco-friendly performance: Our offerings comply with environmental standards, helping to minimize pollution and support sustainable development for enterprises.

Application Scenario

1. Power sector: designed for extreme temperature conditions in various boilers and reactors within thermal power facilities; 2. Metallurgical sector: applicable for linings in iron-smelting furnaces, steel-making furnaces, and various other smelting apparatus; 3. Chemical sector: caters to the petrochemical industry’s demand for high-performance thermal insulation materials, such as those used in cracking furnaces and reactors; 4. Additional industries: appropriate for high-temperature processing equipment utilized in building materials, non-ferrous metals, and waste incineration.